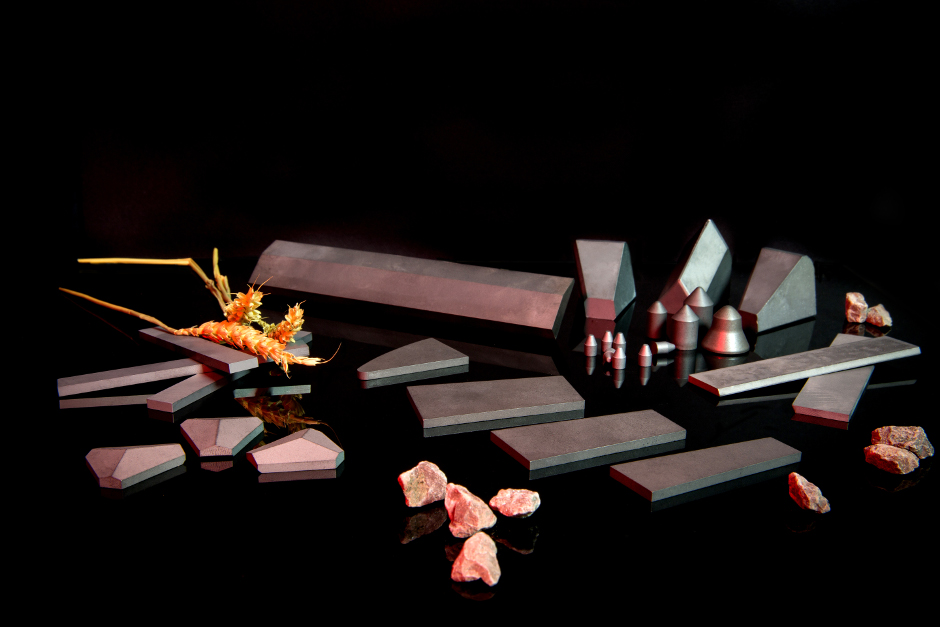

Carbide for stoneworking

Perfect for the most adverse conditions

In addition to carbide plates, carbide pins or carbide inserts, we are able to manufacture drawingspecific special parts at low cost and guarantee high quality and first-class service. We always try to meet the striving for longer durability and the increased demands on the wear resistance of our products by developing new carbide grades for a wide range of applications.

By using our carbides, you can significantly extend the service life of your tools and thus reduce setup costs and downtimes. Our special carbide grades for rock processing and mining have already proven their worth for many years. Convince yourself of our quality and service.

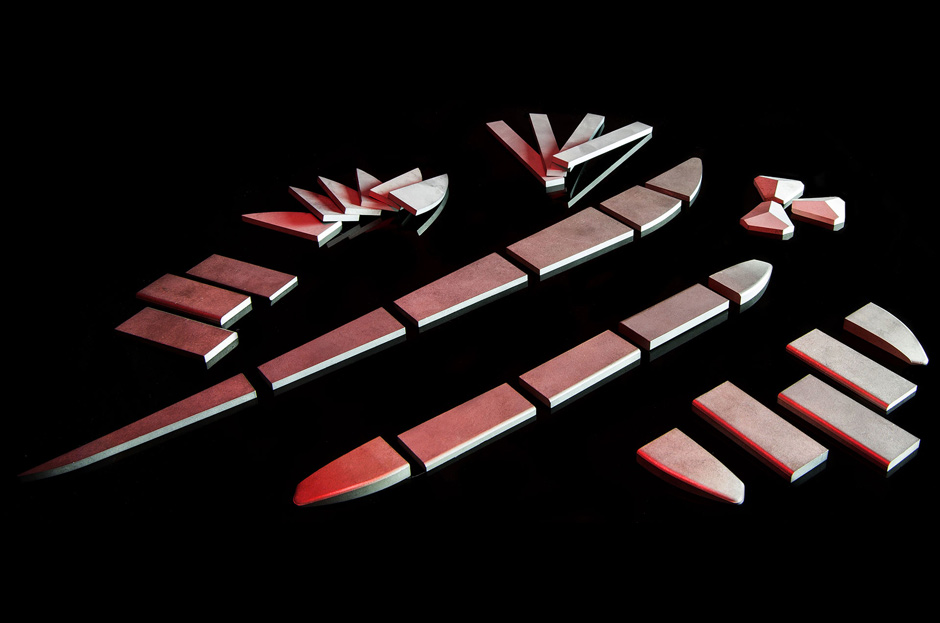

Carbide Plates

Use our carbide for the most adverse conditions. Tungsten carbide plates are ideal for brazing onto steel parts to significantly reduce wear at critical points.

Our B-Grades are ideally suited by their toughness to reduce wear, especially in constant shock and impact. Good examples are tillage in agriculture or crushing of scrap and waste in the recycling industry.

Our plates are available in all possible designs and geometries. We are able to offer special dimensions or alternative grades on request.

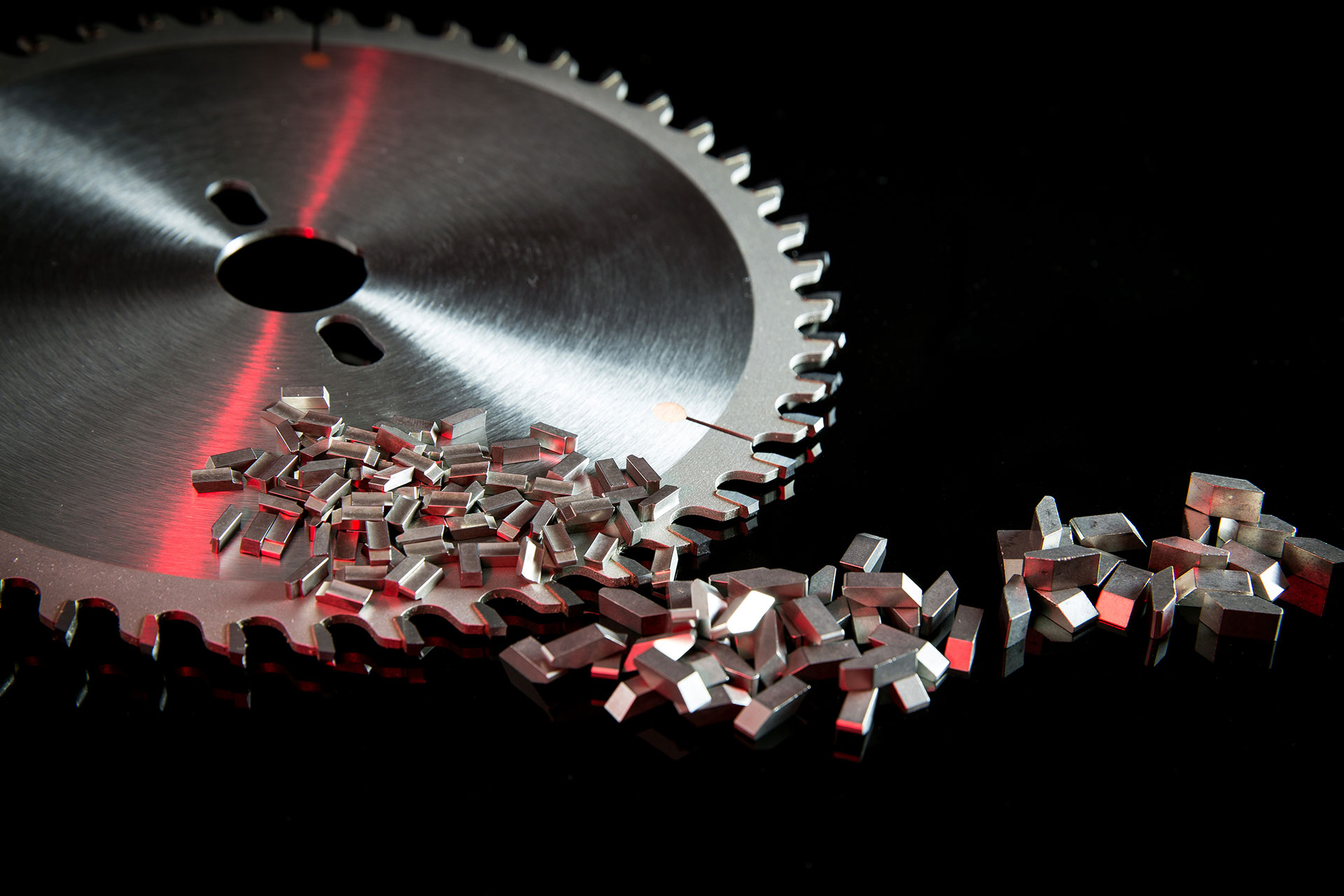

Carbide Parts

In addition to carbide plates, we manufacture special shaped parts such as carbide pins and other drawing-specific special parts. In addition to the quality of our products, our sales staff places special emphasis on providing you with the best possible service.

Send us your inquiries with product drawing, specific requirements and needed quantity.

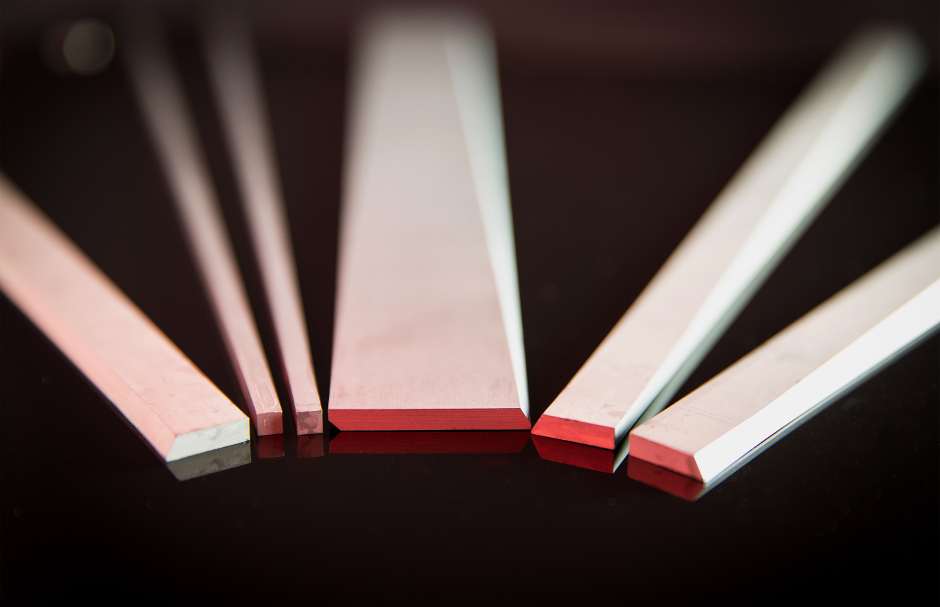

Carbide Scrapers / Strobe Blanks

In addition to woodworking, Strobe Blanks are used to clean dirty surfaces, for example, on conveyor belts. Here they clean the conveyor belt from residues of the conveyed goods, for example gravel and rocks.

Our Strobe Blanks and Bars are therefore also produced in grades that you will not find under a specific category.

Carbide grade overview for stones and mining

| Grade | Grain size | Cobaltcontent % | Density g/cm³ | Hardness | Transverse rupture strenght N/mm² |

Data sheet | ||

| HV30 | HRA | |||||||

| WB20 | Medium+ | 7,8 | 14,8 | 1.260 | 89,0 | 2.250 | ||

| WB30 | Medium+ | 11,5 | 14,3 | 1.120 | 87,6 | 2.700 | ||

| WB40S | Coarse | 12,5 | 14,2 | 1.070 | 87,0 | 2.850 | ||

| WB40 | Medium | 15,0 | 14,0 | 1.120 | 87,6 | 3.000 | ||

| WB40+ | Medium+ | 15,0 | 14,0 | 990 | 86,0 | 2.800 | ||

| WB25G | Coarse | 10,0 | 14,5 | 960 | 85,7 | 2.500 | ||